cast

steel

carbon, manganese and other alloy steels

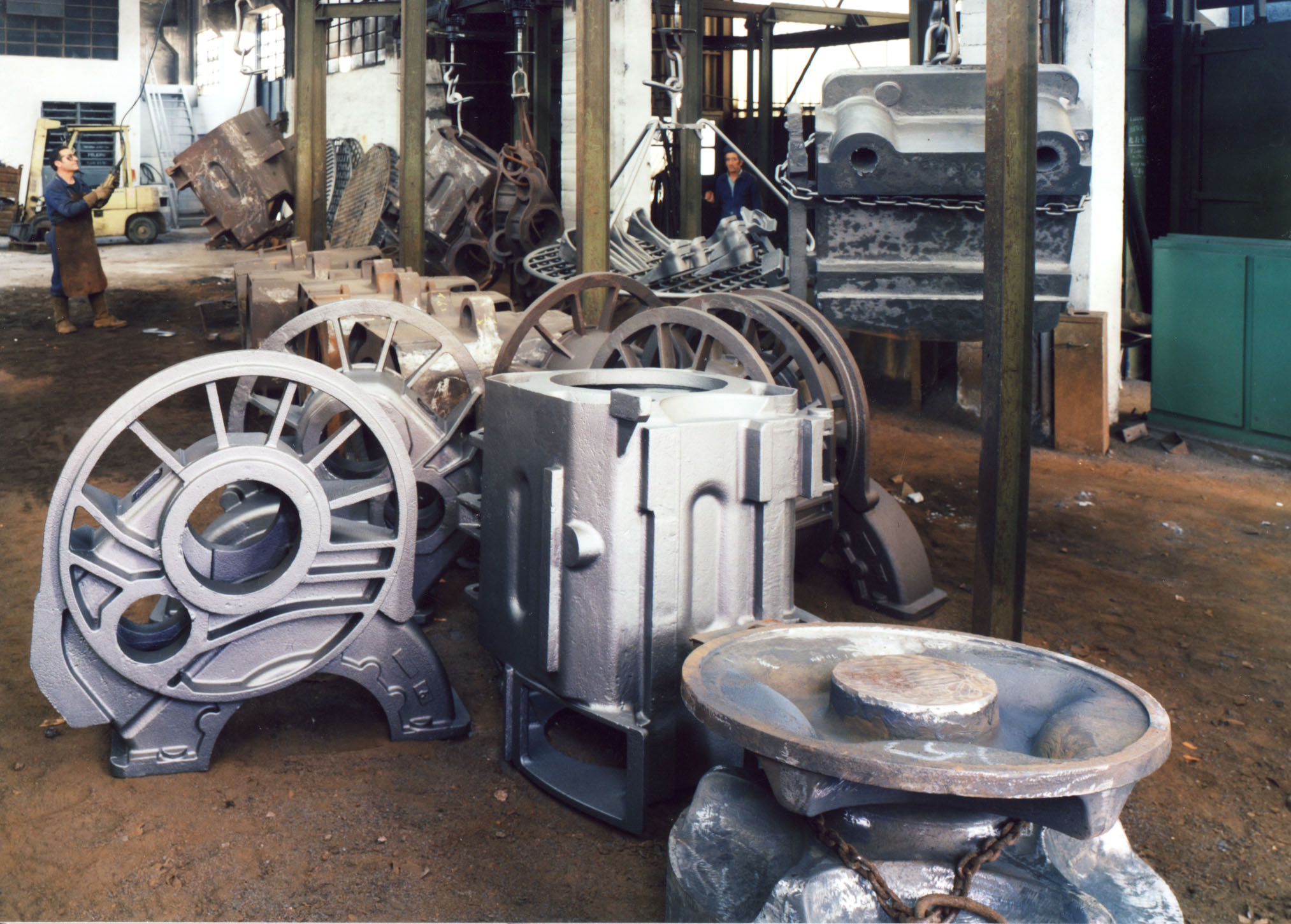

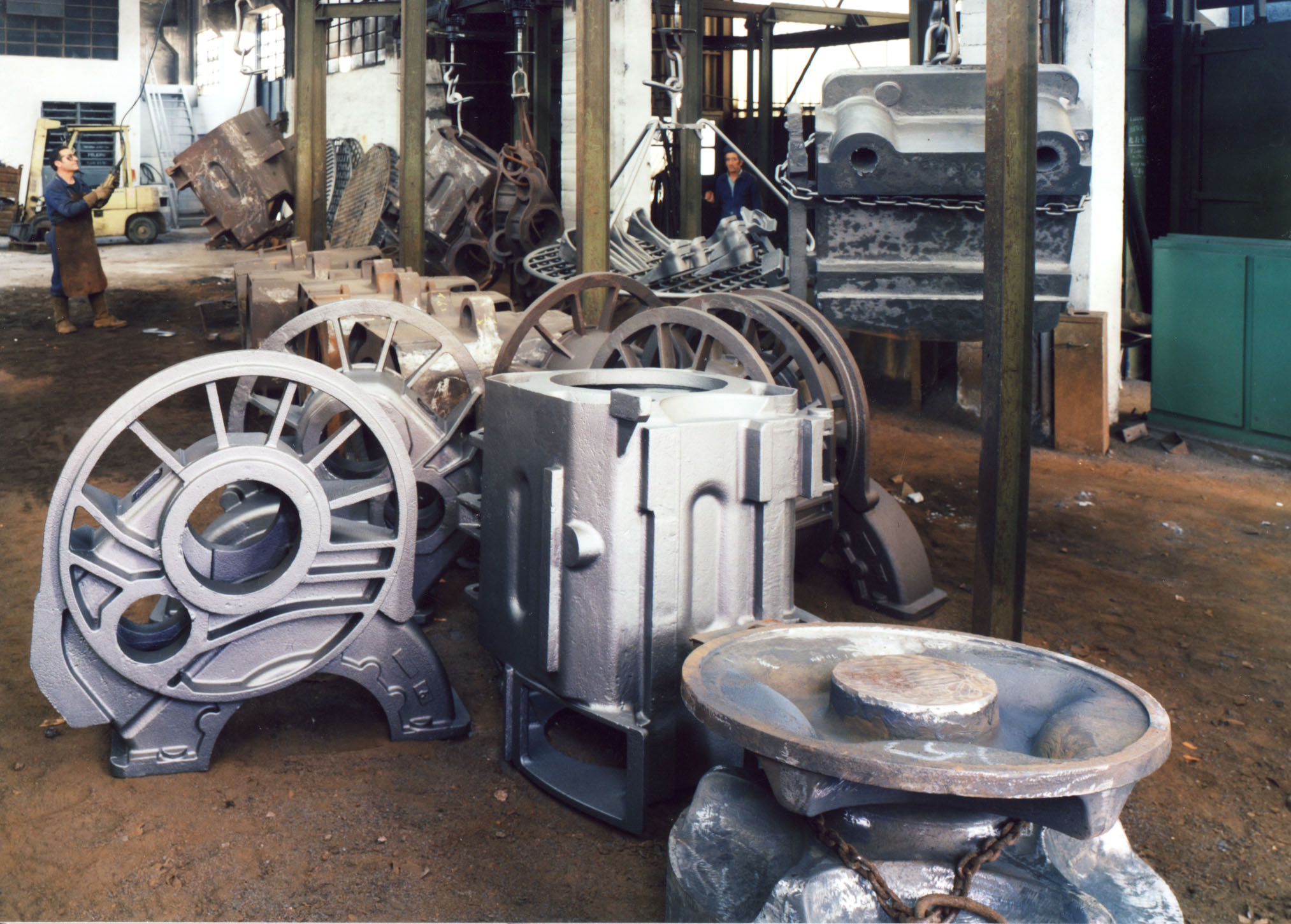

Specialists in the moulding and machining of large parts in short series in carbon, manganese and other alloy steels.

CARBON STEEL

Our experience and knowledge of the special characteristics of carbon steel allow us to undertake the moulding and machining of highly complex parts, such as some electric motor housings, ampoules or dies.

Other common carbon steel parts are railway material and equipment (bogies, axle boxes, etc.), parts for the iron and steel industry and the manufacture of capital goods.

MANGANESE STEEL

Manganese steels, also known as austenitic steels or Hadfield steels, are non-magnetic and non-conductive steels, with an initial hardness of 190 HB ± 25. These steels harden on cold impact up to values of 500 HB, which makes them very suitable for parts that require high resistance to wear and material fatigue.

Such as track switch cores, in which Amurrio is a recognised international leader.

Other common applications for austenitic steels are jaws, bars or cones and bollards, as well as parts for desalination plants, quarries, cement works or mining.

OTHER ALLOYS

We mould parts in any type of alloy steel according to customer specifications, such as parts for dies, housings, shipbuilding, mining, cement, etc.

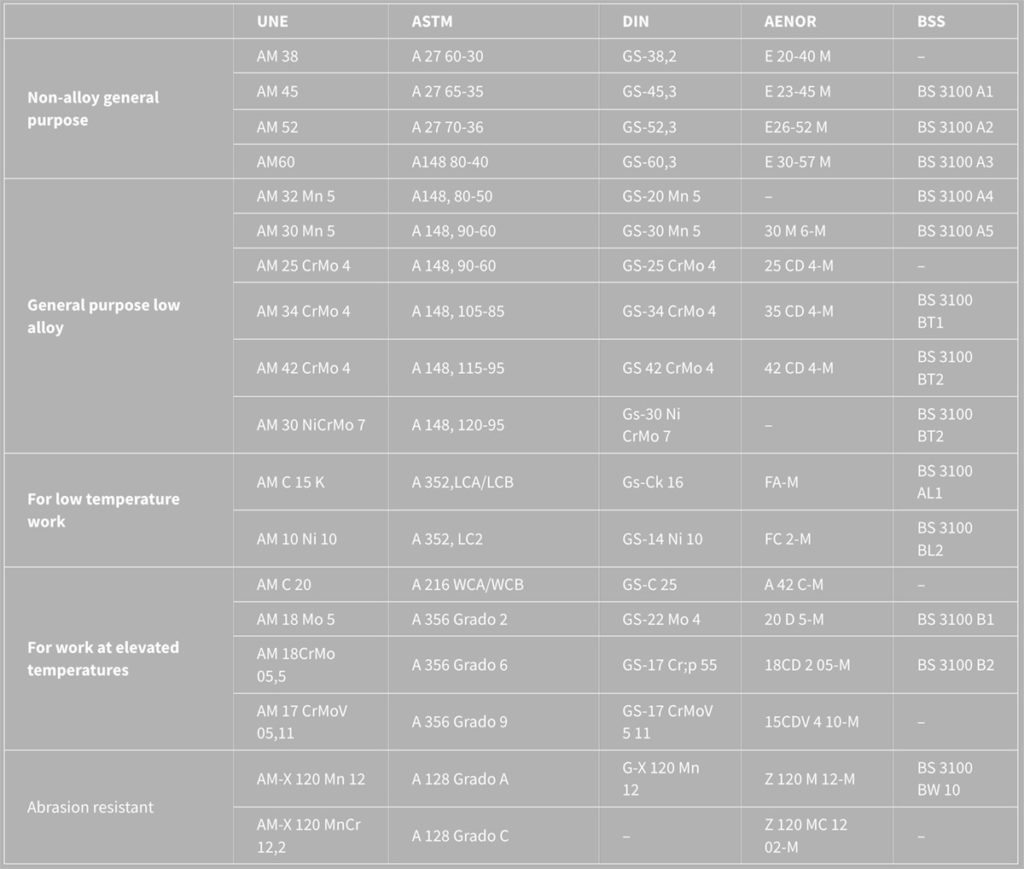

MOST COMMON STEELS:

| UNE | ASTM | DIN | AENOR | BSS | |

| Non-alloy general purpose | AM 38 | A 27 60-30 | GS-38,2 | E 20-40 M | – |

| AM 45 | A 27 65-35 | GS-45,3 | E 23-45 M | BS 3100 A1 | |

| AM 52 | A 27 70-36 | GS-52,3 | E26-52 M | BS 3100 A2 | |

| AM60 | A148 80-40 | GS-60,3 | E 30-57 M | BS 3100 A3 | |

| General purpose low alloy | AM 32 Mn 5 | A148, 80-50 | GS-20 Mn 5 | – | BS 3100 A4 |

| AM 30 Mn 5 | A 148, 90-60 | GS-30 Mn 5 | 30 M 6-M | BS 3100 A5 | |

| AM 25 CrMo 4 | A 148, 90-60 | GS-25 CrMo 4 | 25 CD 4-M | – | |

| AM 34 CrMo 4 | A 148, 105-85 | GS-34 CrMo 4 | 35 CD 4-M | BS 3100 BT1 | |

| AM 42 CrMo 4 | A 148, 115-95 | GS 42 CrMo 4 | 42 CD 4-M | BS 3100 BT2 | |

| AM 30 NiCrMo 7 | A 148, 120-95 | Gs-30 Ni CrMo 7 | – | BS 3100 BT2 | |

| For low temperature work | AM C 15 K | A 352,LCA/LCB | Gs-Ck 16 | FA-M | BS 3100 AL1 |

| AM 10 Ni 10 | A 352, LC2 | GS-14 Ni 10 | FC 2-M | BS 3100 BL2 | |

| For work at elevated temperatures | AM C 20 | A 216 WCA/WCB | GS-C 25 | A 42 C-M | – |

| AM 18 Mo 5 | A 356 Grado 2 | GS-22 Mo 4 | 20 D 5-M | BS 3100 B1 | |

| AM 18CrMo 05,5 | A 356 Grado 6 | GS-17 Cr;p 55 | 18CD 2 05-M | BS 3100 B2 | |

| AM 17 CrMoV 05,11 | A 356 Grado 9 | GS-17 CrMoV 5 11 | 15CDV 4 10-M | – | |

| Abrasion resistant | AM-X 120 Mn 12 | A 128 Grado A | G-X 120 Mn 12 | Z 120 M 12-M | BS 3100 BW 10 |

| AM-X 120 MnCr 12,2 | A 128 Grado C | – | Z 120 MC 12 02-M | – |